Predict. Prevent. Perform.

Innovative consulting and AI-powered tools for engineering teams that demand reliability.

Predict. Prevent. Perform.

Innovative consulting and AI-powered tools for engineering teams that demand reliability.

Innovative consulting and AI-powered tools for engineering teams that demand reliability.

Innovative consulting and AI-powered tools for engineering teams that demand reliability.

BCY Reliability Group, Inc. is an AI-powered infrastructure intelligence company delivering end-to-end visibility, diagnostics, and predictive action across the built environment. We operate two core platforms:

Together, we empower organizations to move from reactive maintenance to predictive reliability—lowering risk, increasing uptime, and reducing cost across millions of square feet of infrastructure.

Our mission is simple:

Predict what’s going to break, prevent it before it happens, and perform with data at every level.

Thousands of commercial and industrial buildings suffer from hidden risks, roof leaks, thermal inefficiencies, material degradation, that go undetected until failure occurs. Traditional inspections are expensive, unsafe, or infrequent. Drone scans require on-site presence, flight restrictions, and heavy coordination. Most companies have no scalable way to monitor asset health across their portfolios.

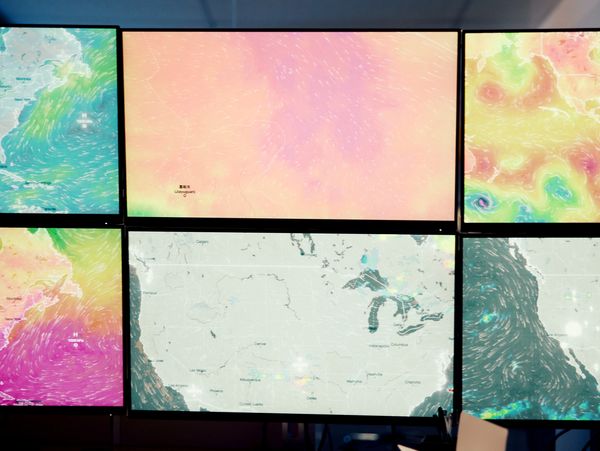

ReliaVue is a patent-pending platform that leverages high-resolution satellite imagery (thermal, RGB, LiDAR, 3D mesh) to deliver AI-powered diagnostics for large-scale infrastructure, without stepping foot on-site. We deliver fast, remote assessments with actionable reports to detect failure progression, heat loss, pooling, degradation, and other risk indicators. Scans are processed in hours, not weeks.

ReliaVue enables risk visibility across thousands of rooftops, warehouses, data centers, and distribution hubs, at a fraction of the cost of drone or manual inspections. It transforms how facility managers, insurers, and ESG leaders make decisions about capital investment, safety, and lifecycle planning.

Our pending patent covers the method and system for combining multi-band satellite data (thermal + RGB + LiDAR) with AI models to detect infrastructure anomalies, assess degradation, and generate predictive alerts, enabling scalable, passive, and comparative diagnostics across any building portfolio on Earth.

Maintenance is reactive. Field technicians rely on scattered SOPs, outdated work orders, and siloed tools to manage complex failures. CMMS platforms are rigid and slow. Most companies lack the ability to turn predictive insight into immediate, technician-level action. Knowledge loss, downtime, and inefficiency are rampant.

ReliaChat is a predictive maintenance platform that combines CMMS integration, technician chat, IIoT alerting, and SOP-guided workflows into one unified experience. Technicians receive real-time fault alerts, recommended fixes, part numbers, and can take action via voice, chat, or wearable. Managers gain live views of OEE, uptime by asset, and crew-level performance, all in one place.

ReliaChat turns insight into execution. When paired with ReliaVue’s remote diagnostics, it enables a closed-loop system: detect failures from orbit and resolve them at the ground level, before they become costly events. It empowers technicians, reduces mean time to repair (MTTR), and dramatically improves plant reliability and uptime.

Our provisional patent protects the workflow and system architecture for:

This makes ReliaChat the first platform to link predictive scans, technician communication, and work execution into a live, AI-augmented reliability network.

BCY Reliability Group’s two platforms work in tandem to redefine what modern reliability means. From the skies to the shop floor, we deliver scalable diagnostics, predictive intelligence, and real-time action—powered by AI, delivered through expert consulting, and secured by patent-pending IP.

At BCY Reliability Group, we partner with industries where uptime is critical, failure is costly, and visibility into asset health is often limited. From global warehouse networks to data centers, from rooftop assets to municipal infrastructure, our patented platforms, ReliaVue and ReliaChat, deliver scalable, predictive solutions that turn engineering insight into operational excellence.

The Challenge:

Facilities with massive square footage and aging infrastructure struggle to detect early signs of thermal loss, equipment degradation, and roof failures. Downtime due to electrical, HVAC, or mechanical failure can cost millions. Maintenance is often reactive and disjointed.

Our Impact:

The Challenge:

Owners and facility managers oversee thousands of assets across geographies—with no easy way to assess risk, prioritize repairs, or validate vendor work. Manual inspections are time-consuming, inconsistent, and often miss early warning signs.

Our Impact:

The Challenge:

High-velocity fulfillment operations can’t afford outages, yet rooftop HVAC failures, internal power faults, and structural issues go unnoticed until they disrupt operations. Maintenance teams are stretched thin and rely on tribal knowledge.

Our Impact:

The Challenge:

Downtime at a data center isn’t just expensive—it’s catastrophic. Yet many critical systems (roofing, cooling, UPS) aren’t continuously monitored for structural integrity. Manual inspections and isolated telemetry leave blind spots.

Our Impact:

The Challenge:

Cities, school districts, and public agencies often manage hundreds of aging buildings on limited budgets. They lack the data to justify capital repairs, prevent emergencies, or track building health over time.

Our Impact:

The Challenge:

Clean energy systems, especially rooftop solar, rely on stable, well-maintained surfaces. But the supporting roofs are rarely monitored, and ESG teams struggle to validate asset performance and resilience.

Our Impact:

Our Mechanical Engineering team delivers innovative, reliable solutions for equipment design, failure analysis, and field reliability improvement. We focus on optimizing performance and safety while reducing unplanned downtime and lifecycle costs through advanced diagnostics and materials analysis.

We support clients with robust electrical engineering services—from predictive failure modeling and power distribution design to sensor integrations and panel diagnostics. Our expertise spans critical systems, asset grounding, and electrical safety optimization across industrial environments.

Our Software Engineering group builds scalable, secure, and AI-powered platforms that enhance field maintenance, telemetry, and infrastructure analytics. We specialize in integrating CMMS, IIoT, and cloud workflows into cohesive tools like ReliaChat and ReliaVue.

ReliaVue delivers remote assessments at scale using satellite-based thermal, RGB, and 3D mesh data. We help clients monitor structural integrity, thermal leakage, storm damage, and aging risks without drones or site access. All data feeds into AI-powered reports for CapEx, ESG, or insurance planning.

ReliaChat is our AI-guided technician platform for predictive maintenance and team coordination. It integrates with CMMS systems, wearable devices, telemetry feeds, and SOP workflows to alert technicians before failures occur and ensure fast, standardized resolution on the ground.

We deploy custom AI models and reliability analytics to predict failures, classify risk levels, and prioritize intervention. From satellite scan analysis to technician-level alert scoring, our tools are built to reduce costs, improve uptime, and close the loop from insight to action.

We love our customers, so feel free to visit during normal business hours.

3101 N Central Ave STE 183 Phoenix, Arizona 85013

Phone: (317) 340-3255 Email: jyarbrough@thebcygroup.com

Open today | 09:00 am – 05:00 pm |

Get 10% off your first purchase when you sign up for our newsletter!

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.